Data AnalyticsThe data can be leveraged for multi - dimensional data analytics, enabling comprehensive management planning. It can also be used for predicting future events or analyzing emerging trends.

Data AnalyticsThe data can be leveraged for multi - dimensional data analytics, enabling comprehensive management planning. It can also be used for predicting future events or analyzing emerging trends. Alerts and NotificationReceive Real-Time notifications in the event of machinery issues through Line, Email, and a web application, ensuring prompt awareness and immediate problem resolution.

Alerts and NotificationReceive Real-Time notifications in the event of machinery issues through Line, Email, and a web application, ensuring prompt awareness and immediate problem resolution.

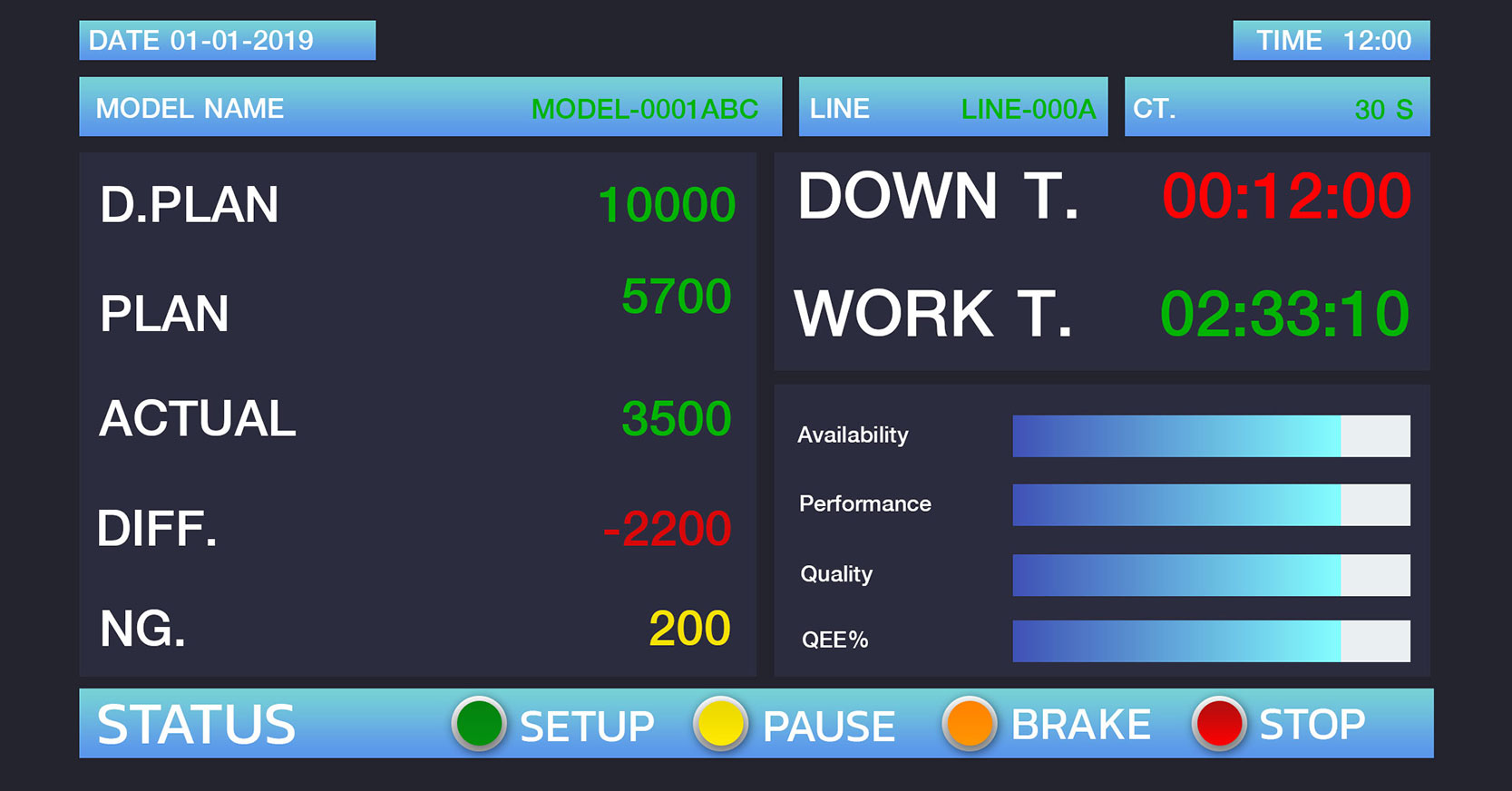

Target/ Daily Plan Ability to display daily production targets, for example, 50,000 pieces per day, allowing operators to visualize daily production goals.

DiffIt represents the variance between the 'Plan' and 'Actual' values, for example, Plan = 2000, Actual = 1300, Diff = 700, enabling operators to ascertain the shortfall towards meeting the predetermined target.

Cycle time , Takt time (CT)Provide relevant personnel and production supervisors with information about the Takt Time/Cycle Time.

Date , Clock TimeDisplay the date and time in a Digital Clock format to inform employees of the working hours.

Plan (Cycle Time)The production plan according to the Cycle Time will continuously increment based on the specified Cycle Time, starting from 0. For example, if the Cycle Time is 3 minutes/piece, every 3 minutes, the Plan will increase by 1. For instance, after 30 seconds, the Plan (Cycle Time) will stand at 10 pieces.

ActualDisplay real-time production output, which can receive input (On/Off Contact) from Push Button, Photo Sensor, Custom Barcode Scanner, or Limit Switch.

Production Lines Monitoring Facilitate an overview of production without the need to individually inspect each line, allowing for effective grouping.

Model NameClearly display the Model Name currently in production to minimize production errors, as it enables operators to know which model is being produced.

Downtime MonitoringIt is a feature that provides real-time notification when downtime occurs in the production line, displaying it on the screen, accompanied by an audible alert. It also records downtime from start to stop, calculates total downtime, and logs the reasons for the downtime, ensuring accurate data for future improvement efforts. Additionally, it can be extended to include Tower Lights and Signal Horns.

AvailabilityIt can display the Availability metric, which is the comparison between Operating Time and Loading Time, calculated as 90%.

AvailabilityIt can display the Availability metric, which is the comparison between Operating Time and Loading Time, calculated as 90%. QualityIt can display the Quality metric, which measures the ability to produce goods that meet customer specifications, compared to the total quantity produced. The suitable value is at 99%, utilizing Photo Sensor and Machine Input.

QualityIt can display the Quality metric, which measures the ability to produce goods that meet customer specifications, compared to the total quantity produced. The suitable value is at 99%, utilizing Photo Sensor and Machine Input. PerformanceIt can display the Performance metric, which assesses the machinery's performance by comparing Net Operating Time to Operating Time. The suitable value is at 95%.

PerformanceIt can display the Performance metric, which assesses the machinery's performance by comparing Net Operating Time to Operating Time. The suitable value is at 95%.